+91-471-2490572 |

principal@sctce.ac.in

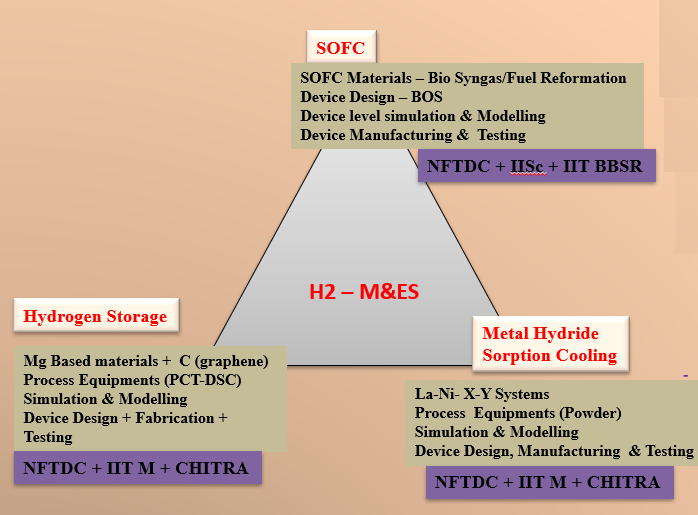

The DST – NFTDC Centre for Materials & Energy Storage Platforms (MECSP / H2) focuses on translational R&D from Technology Readiness Level (TRL) 3 to TRL 7. It integrates core competencies in materials, processes, and product design to develop hydrogen-based energy devices and systems. The centre emphasizes Material-Process-Product integration and optimization, dovetailing multiple materials and processes into functional product designs.

The projects are executed under three main Work Packages (WP):

These work packages involve collaboration among five institutions for comprehensive Materials–Process–Product Integration.

Conduct state of art TRL 3-7 translational R & D in Materials to H2 based Energy Devices in the area of SOFC, H2 Storage and Metal Hydride sorption cooling

Conduct Research & Development of novel materials as composites, graded materials, mixtures, materials + catalysts around the well – proven base materials to meet the figure of merit for SOFC, H2 storage and Metal – Hydride sorption cooling

Four centres, IISc, Bangalore, IIT M, Chennai, IIT Bhubaneswar and Sree Chitra Thirunal College of Engineering, together with NFTDC have appropriate core competence, decade(s) of experience, infrastructure facilities and proven track record to handle the problems chosen in this consortium.

TRL 3-7

Principal Investigator & Co-Principal Investigators:

.png)

Principal Investigator

Dr. K. Balasubramanian

NFTDC, Hyderabad

.png)

Co-PI

Prof. S. Dasappa

IISc, Bangalore

.png)

Co-PI

Prof. MP Maiya

IIT Madras, Chennai

.png)

Co-PI

Dr. Soobhankar Pati

IIT Bhubaneswar

.png)

Co-PI

Prof. G. Mohan

SCTCE, Thiruvananthapuram